Thank you for reading this post, don't forget to subscribe!

First step to using carbon fiber? Whether building new parts or fixing broken ones, you need to start with the right type–and that means understanding weave type.

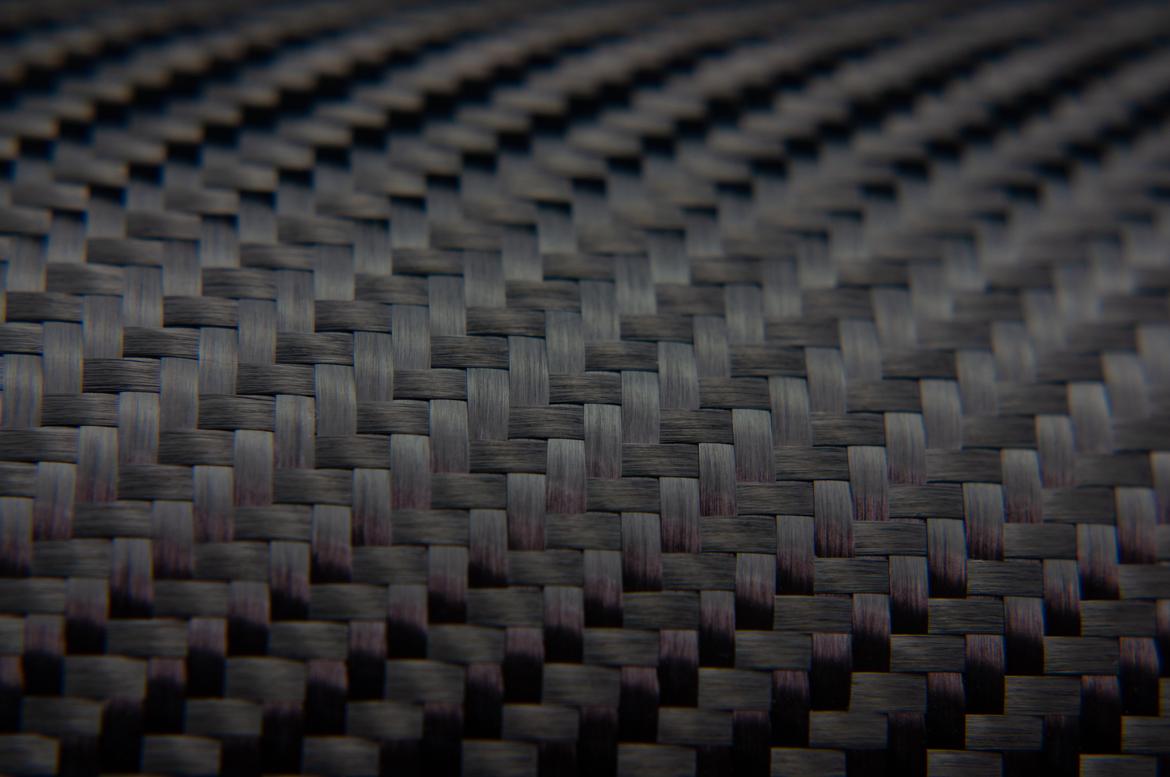

A carbon-fiber weave refers to how the bundles of carbon fibers, known as tows, are woven together to create sheets. Each weave has different properties and benefits.

Plain Weave

Does your project lack complex curves but need high stability–like repairing a door or creating aero panels? Plain weave could be the way to go.

Its simple over-under tow pattern–woven like a basket–provides high stability, easy draping and uniform strength distribution. However, it’s not best suited for areas that have complex curves–picture trying to mold a piece of card stock around a ball.

Twill or Satin Weave

If complexity is what you need, consider using twill weave or satin weave. Although twill weave features a similar over-under theme, it uses a diagonal pattern. This pattern features a single horizontal tow of carbon, known as a weft direction, alternating over and under two or three of the primary vertical structural tows, known as a warp direction.

Thanks to this diagonal interlocking, twill weave offers higher durability, better drapability and greater visual appeal. The downsides? Lower stability, reduced stiffness and increased cost. This is why most twill weave is used for pieces that need to be light and strong–so body panels, splitters or suspension components.

Harness-Satin Weave

The third most common weave pattern is harness-satin weave. While similar to plain weave, this type has long float lengths–this means that the weft tow passes over multiple warp tows without interlacing, generally at four, five and eight intervals, known as 4HS, 5HS and 8HS.

These floats create a smoother, almost glossy surface finish. 8HS weave allows for one of the most flexible structures for complex geometry and improved load transfer.

The downsides? Satin weave isn’t just difficult to work with because it’s prone to snagging and fraying. It’s also more expensive and offers less stability in multiple directions–hence why you’ll see it in more interior component projects.

Unidirectional vs. Bidrectional vs. Multidirectional Weaves

Unidirectional carbon weave is less of a weave. Rather, it’s when all the fibers are oriented in the same direction, hence, unidirectional. Project-wise, this type of weave should be used when the load forces come from one direction.

That’s right, carbon weave is further complicated with fiber orientation–the direction in which the fibers point.

Plain, twill and harness-satin weaves are normally woven with fibers oriented at 90 degrees to one another, known as bidirectional.

Meanwhile, more complex patterns, where structural elements run in three or more directions, offer enhanced load capabilities and are known as multidirectional.

In the end, the more complex the weave pattern, the stronger your final product will be. But keep in mind that it will be more expensive and prone to falling apart during handling.